Variation Analysis

Ensure parts fit and work properly together – the first time.

Ensure parts fit and work properly together – the first time.

- Product and process optimization

- Feature based model before or after geometry is available

- Identify critical dimensions

- Simulation of the assembly process

- Prediction of assembly quality

Knowing when you can relax tolerances and eliminate expensive machining processes – without sacrificing product quality – is a consistent goal of quality planning. Each time you optimize the balance between these factors, design quality increases and total cost of quality decreases. With Variation Analysis, your design teams can define and analyze all dimensional characteristics in a CAD neutral environment. This provides a highly flexible solution for defining optimal product and manufacturing strategies having a positive impact on total cost of quality. Leveraging product and manufacturing information embedded in the CAD model also provides accuracy and efficiency for downstream processes.

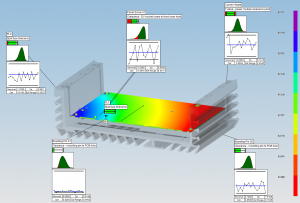

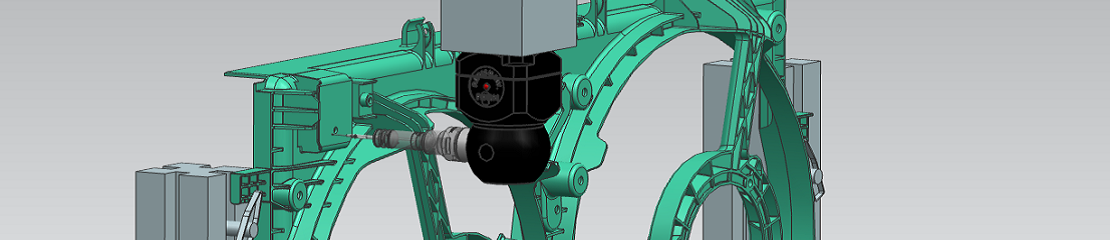

With Variation Analysis, a 3D digital prototype is created to simulate the production build process. The digital prototype includes a comprehensive representation of geometry, product variation (tolerances), assembly process variation (sequence, assembly attachment definition, tooling) and measurements. The model is used to predict if there will be any assembly build problems – before any physical parts are made or tooling is cut. It also identifies the root causes of the build problems and enables the design, tolerances and assembly process to be optimized very early in the product development process.

With Variation Analysis, a 3D digital prototype is created to simulate the production build process. The digital prototype includes a comprehensive representation of geometry, product variation (tolerances), assembly process variation (sequence, assembly attachment definition, tooling) and measurements. The model is used to predict if there will be any assembly build problems – before any physical parts are made or tooling is cut. It also identifies the root causes of the build problems and enables the design, tolerances and assembly process to be optimized very early in the product development process.

Optimize product and process

Variation Analysis allows users to identify dimensional problems early in the design cycle, avoiding assembly build and quality issues due to excessive variation. With this solution, design flaws can be caught before committing to tooling.

Identify critical dimensions

Variation Analysis identifies critical dimensional, tolerance and assembly processes that are key contributors to variation. These areas have a significant impact on product quality and therefore warrant careful monitoring.

Reduce costs

Variation Analysis reduces cost by improving product quality and accelerating time-to-market. In addition, manufacturing costs can be reduced by maximizing allowable part tolerances, while still controlling critical assembly dimensional specifications. Controlling these dimensional characteristics helps minimize scrap, rework and warranty defects. With Variation Analysis, product quality is significantly improved by ensuring that parts fit and work together properly – the first time.

No other dimensional analysis solution on the market:

- Works in a CAD-neutral, graphically rich digital prototyping environment

- Provides feature-based capabilities using tolerances based on GD&T

- Supports over- and under-constrained static and kinematic assembly operations

- Links to FEA solvers for comprehension of component flexibility

Technical Solution Overview

Teamcenter lifecycle visualization suite

Teamcenter CAD-neutral lightweight visualization environment allows the geometry from multiple sources to be included in the analysis. In addition, this enables the analysis of large assemblies and leverages many of the digital mockup capabilities such as cross section, 3D clearance/markup/measure, etc.

Geometric tolerancing capability

Variation Analysis supports feature-based modeling with the features varied based on geometric dimensioning and tolerancing (GD&T). Key tolerancing aspects supported include maximum material condition, composite position and profile, multiple datum reference frames, unilateral/unequal bilateral surface profile.

ConJoin assembly constraint engine

ConJoin is an equation-based, generic assembly solver for over- and under-constrained static and kinematic assembly constraints using a single common user interface.

Flexible component capability

Through integrating with many FEA solvers, Variation Analysis is able to comprehend component flexibility due to clamping, welding and springback.

For further information please visit the Siemens PLM – Variation Analysis site here.

Ensure parts fit and work properly together – the first time.

Ensure parts fit and work properly together – the first time.